-

JC-Y Industrial Oil Mist Purifier

Industrial oil mist purifier is an environmental protection equipment designed for oil mist, smoke and other harmful gases generated in industrial production. It is widely used in mechanical processing, metal manufacturing, chemical and pharmaceutical industries, and can effectively collect and purify oil mist, improve the working environment, protect employee health, and reduce production costs.

-

JC-SCY The all-in-one Cartridge Dust Collector

The integrated cartridge dust collector is an efficient and compact industrial dust removal equipment that integrates the fan, filter unit and cleaning unit into a vertical structure, with a small footprint and easy installation and maintenance. This type of dust collector usually adopts a one-button start and stop operation, which is simple and easy to understand and suitable for fume purification and control such as welding, grinding, and cutting. Its filter cartridge is installed with a skeleton, with good sealing performance, long filter cartridge service life, and easy installation and maintenance. The box design focuses on air tightness, and the inspection door uses excellent sealing materials with low air leakage rate, ensuring efficient dust removal effect. In addition, the inlet and outlet air ducts of the integrated cartridge dust collector are compactly arranged with low airflow resistance, which further enhances its operating efficiency. This dust collector has become an ideal choice for dust control in metal processing and other industries with its efficient filtering performance, stable operation and convenient maintenance.

-

JC-BG Wall-mounted Dust Collector

A wall-mounted dust collector is an efficient dust removal device that is mounted on the wall. It is favored for its compact design and powerful suction power. This type of dust collector is usually equipped with a HEPA filter that can capture fine dust and allergens to keep the indoor air clean. The wall-mounted design not only saves space, but also blends in with the interior decoration without looking obtrusive. They are easy to install and maintain, and users only need to replace the filter and clean the dust box regularly. In addition, some high-end models also have smart features such as automatic adjustment of suction power and remote control, making it more convenient to use. Whether it is a home or office, a wall-mounted dust collector is an ideal choice to improve air quality.

-

JC-XZ Mobile Welding Smoke Dust Collector

Mobile welding fume collector is an environmentally friendly device designed for welding operations, which is designed to effectively collect and filter harmful fumes and particulate matter generated during welding. This equipment is usually equipped with a high-efficiency filtration system that can capture tiny fume particles, reducing harm to workers’ health and pollution to the working environment. Due to its mobile design, it can be flexibly moved according to the needs of welding operations and is suitable for various welding sites, whether it is a factory workshop or an outdoor construction site.

-

JC-JYC skeleton external suction arm

Features Equipment name: JC-JYC skeleton external suction arm Equipment length: 2m, 3m, 4m Equipment diameter: Φ150mm Φ160mm Φ200mm (other specifications need to be customized). Outer pipe material: Imported PVC steel wire air duct, corrosion-resistant, acid and alkali resistant, temperature resistant to 140 ℃. Note: We are committed to continuous product updates and can provide various forms of suction arms according to the require of customers. -

JC-JYB wall mounted flexible suction arm

Features Equipment name: JC-JYB wall mounted flexible suction arm Connection method: Fixed bracket connection (sealed by elastic rubber ring) Cover form: conical suction (A), horseshoe suction (L), plate suction (T), top hat suction (H) Other forms of masks can be customized. Hood equipped with air volume regulating valve Equipment length: 2m, 3m, 4m (extended arms are required for 4m and above, with a length of up to 10m) Equipment diameter: Φ150mm Φ160mm Φ200mm (other specifications ne... -

Filter bag for dust collector

Product Highlights 1.Strong wear resistance: Polyester cloth bags have excellent wear resistance, can withstand large tensile and frictional forces, and are not easily worn or damaged. 2.Good corrosion resistance: Polyester cloth bags can resist the erosion of corrosive substances such as acid, alkali, and oil, and can maintain a long-term service life. 3.High tensile strength: Polyester bags have high tensile strength, can withstand large weight and pressure, and are not easily deformed... -

Cartridge filter for dust collector

The unique concave fold pattern design ensures 100% effective filtration area and maximum operating efficiency. Strong durability, using advanced foreign technology to prepare specialized filter cartridge adhesive for bonding. The optimal fold spacing ensures uniform filtration across the entire filtration area, reduces filter element pressure difference, stabilizes airflow in the spray room, and facilitates cleaning of the powder room. The folding top has a curved transition, which increases the effective filtration area, maximizes filtration efficiency, and prolongs service life. Rich in elasticity, low hardness, single ring sealing ring.

-

Downdraft table

It is suitable for various welding, polishing, polishing, plasma cutting and other processes. This product adopts internationally leading filtration technology, with a filtration efficiency of 99.9% for welding, cutting, and polishing smoke and dust, while ensuring extremely high air flow rate.

-

JC-NX welding smoke purifier

The JC-NX mobile welding smoke and dust purifier is suitable for purifying smoke and dust generated during welding, polishing, cutting, polishing, and other processes, as well as recovering rare metals and precious materials. It can purify a large amount of small metal particles suspended in the air that are harmful to the human body, with a purification efficiency of up to 99.9%.

-

JC-NF high negative pressure purifier

High vacuum smoke and dust purifier, also known as high negative pressure smoke and dust purifier, refers to a high-pressure fan with a negative pressure greater than 10kPa, which is different from ordinary welding smoke purifiers. The JC-NF-200 high negative pressure smoke and dust purifier adopts two-stage separation and is a dust removal equipment designed specifically for dry, oil-free, and corrosion-free welding smoke generated during welding, cutting, and polishing processes.

-

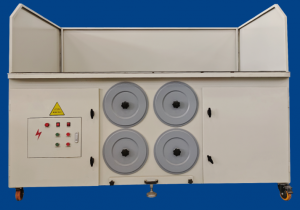

JC-XPC multi-cartridge dust collector (without blower and motor)

JC-XPC multi-cartridge dust collector is widely used in machinery, foundry, metallurgy, building materials, chemical industry, automobile, shipbuilding, equipment manufacturing and other industries in the arc welding, CO2 protection welding, MAG protection welding, special welding, gas welding and cutting of carbon steel, stainless steel, aluminum and other metal welding fume purification treatment.