Manufacturer for Dust Collector In Thermal Power Plant - Self-cleaning Air Filter Element – Jiongcheng

Short Description:

Manufacturer for Dust Collector In Thermal Power Plant - Self-cleaning Air Filter Element – Jiongcheng Detail:

Description

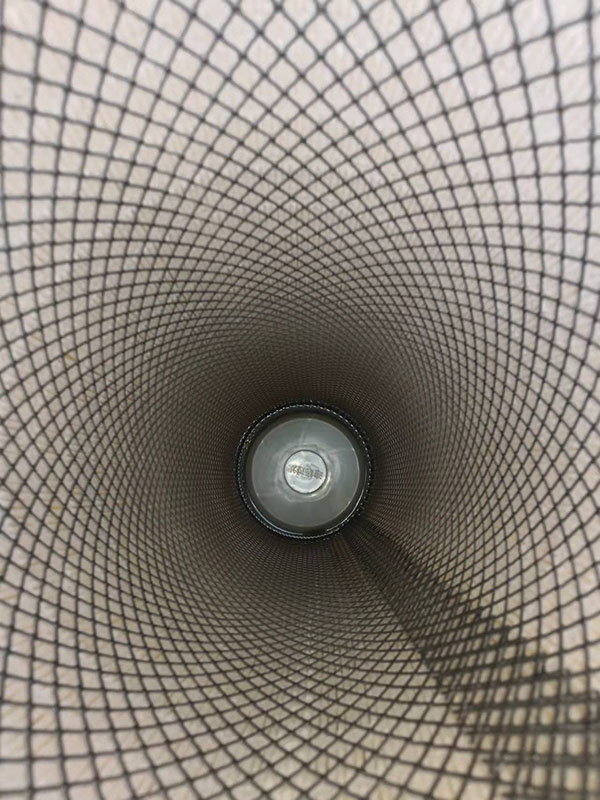

Dust collector filter elements and self clean filter elements are made by JCTECH factory itself(Airpull). It is precisely design for wide filtration surface and big air flow rate with its self researched filtration material and structures. Diffferent caps are availabe for different operation patterns. All items are marked Replacement or Equivalent and are not affiliated with the original equipment manufacture, part numbers are for cross reference only. JCTECH filters are made from a premium blend of flame retardant cellulose and polyester media. This material is especially designed for back pulse operations, and offers enhanced stability and structural integrity. All cellulose blend filters are dimpled pleated. This pleat lock helps maintain pleat spacing during operation. This is an aftermarket replacement filter for dust collector models including Donaldson Torit Model Downflow II or DFT 2, AerTable (Round Access Cover), CX, Downdraft Bench 2000 and 3000, Uniwash / Polaris Intercept Dust Collectors, and many manufacturers if equipment that use the same size filter.

|

Number |

Design project |

Design Parameter |

|

1 |

Specification |

Ø320*1000 |

|

2 |

Fixed air volume |

1500N.m³/H/T |

|

3 |

Initial resistance |

≤150PaM |

|

4 |

Operation resistance |

150-650Pa |

|

5 |

End resistance |

≥850pa |

|

6 |

Filter accuracy |

2 Micorn |

|

7 |

Filter efficiency |

PM2.0≥99.99% |

|

8 |

Replacement cycle |

12-18 mouths |

|

9 |

Withstand the backflush pressure |

≤0.8MPa |

|

10 |

Monthly average highest humidity |

≤80% |

|

11 |

Working temperature |

-35℃~+65℃ |

|

12 |

Filter paper |

US HV Filter FA6316 |

|

13 |

Filter area |

27 ㎡ |

|

14 |

Folds |

280 |

|

15 |

Folds’height |

48mm |

|

16 |

Structure |

Rhombus Steel Mesh, Material Q195 Surface treatment: zincification |

|

17 |

Gluid |

Two-component polyurethane |

|

18 |

Gasket |

EPDM (Boom type), ≥80% Rebound rate Polyurethane (snap-in type)≥85% Rebound rate |

|

19 |

End cap material |

SECCN5/δ0.8(Boom type) Enhanced ABS/white (Snap type) |

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Manufacturer for Dust Collector In Thermal Power Plant - Self-cleaning Air Filter Element – Jiongcheng, The product will supply to all over the world, such as: kazakhstan, Armenia, Muscat, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!