Rapid Delivery for Dust Collector Motors - Cartridge Dust Collector – Jiongcheng

Short Description:

Using high-performance additives and highly refined base oil formula, it has good oxidation stability and high temperature stability, provides good protection and excellent lubricity for compressor oil, the working time is 4000 hours under standard working conditions, suitable For screw air compressors with power less than 110kw.

Rapid Delivery for Dust Collector Motors - Cartridge Dust Collector – Jiongcheng Detail:

Overview

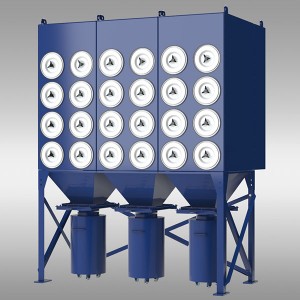

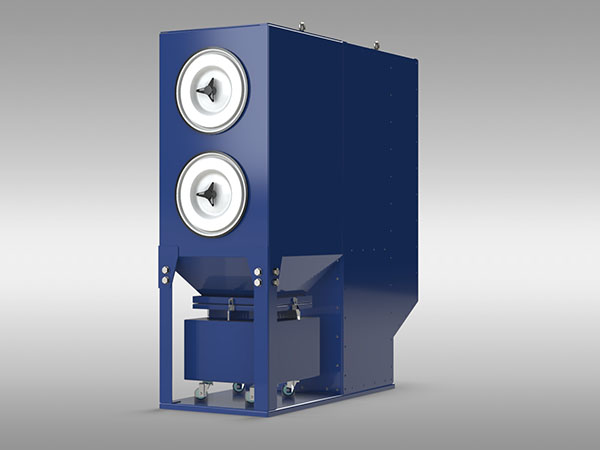

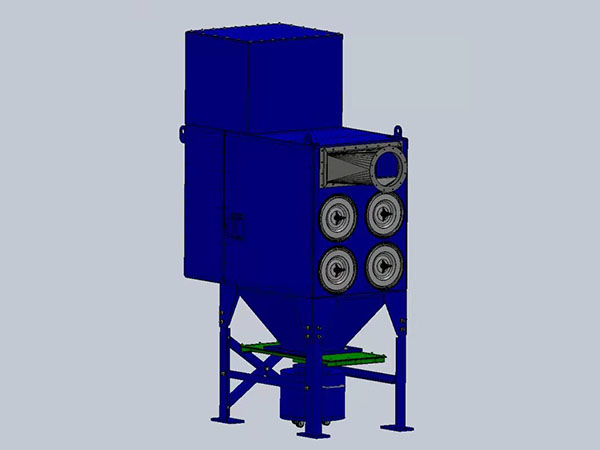

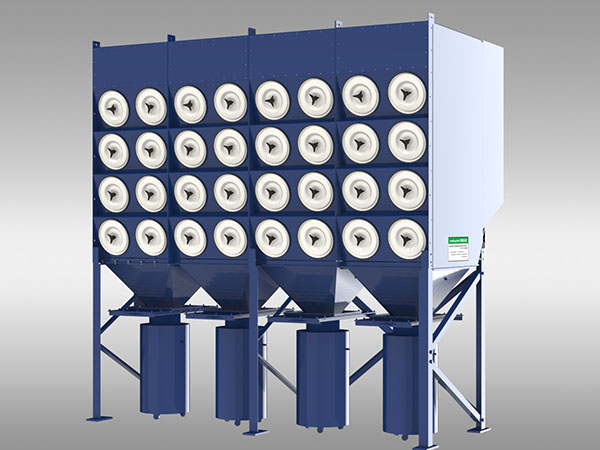

The cartridge type dust collector is also called the magazine type dust collector or the filter cartridge type dust collector. The main features are as follows:

1. The vertical filter cartridge structure is used to facilitate dust absorption and dust removal; and because the filter material shakes less during dust removal, the life of the filter cartridge is much longer than that of the filter bag, and the maintenance cost is low.

2. Adopting the current international advanced three-state off-line cleaning method (filtering, cleaning, static) to avoid the “re-adsorption” phenomenon during cleaning, making the cleaning completely reliable.

3. Designed with a pre-dust collection mechanism, which not only overcomes the shortcomings of direct dust scouring and easy to wear the filter cartridge, but also can greatly increase the dust concentration at the entrance of the dust collector.

4. Imported parts are used for the key components that affect the main performance (such as pulse valve), and the service life of the diaphragm of the vulnerable part exceeds 1 million times.

5. Adopting separate spraying and cleaning technology, one pulse valve can spray one row at the same time (the number of filter cartridges in each row is up to 12), which can greatly reduce the number of pulse valves.

6. The three-state ash cleaning mechanism of the pulse valve adopts PLC automatic control, and has two control modes, timing or manual, to choose from.

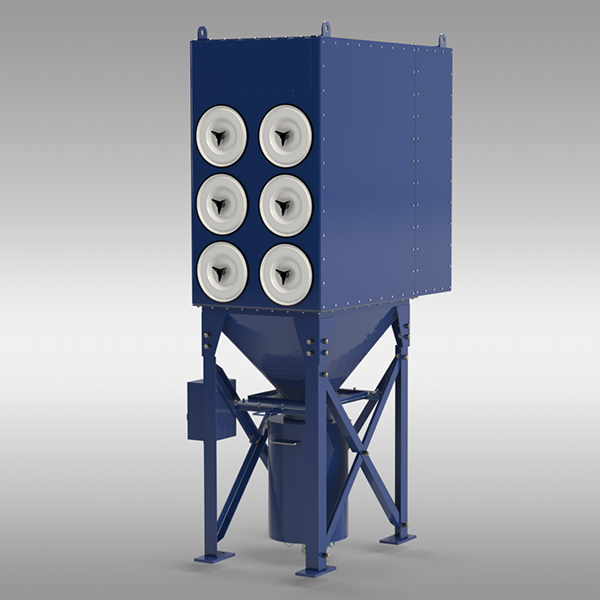

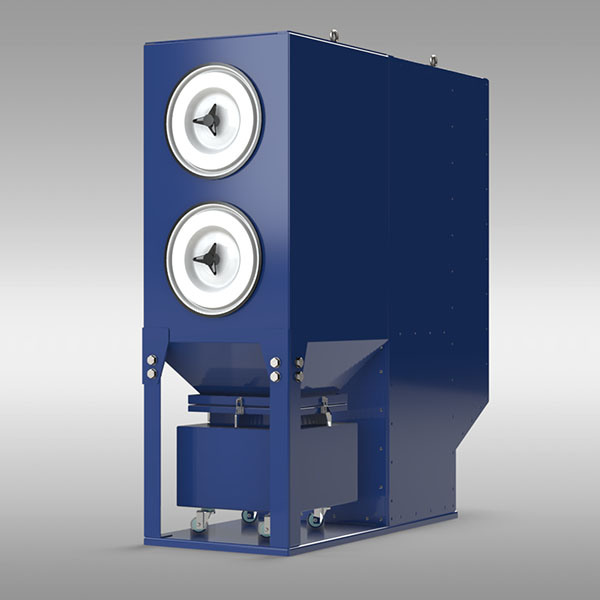

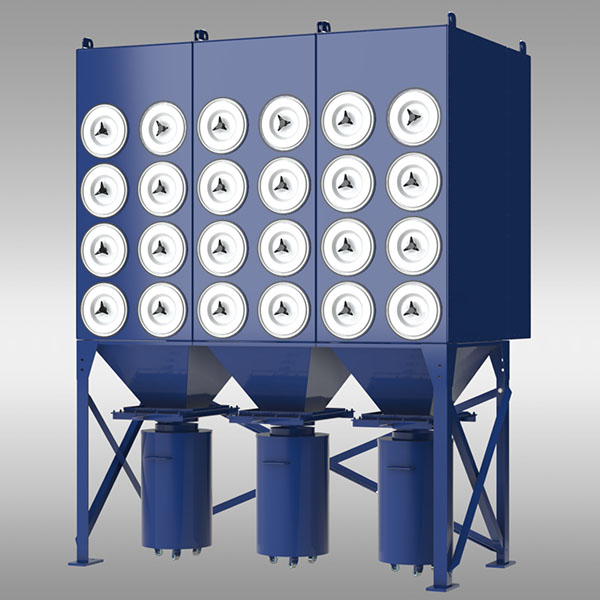

7. Any combination of filter cartridges with different numbers of columns and rows can be used according to the needs of the installation space; the three-dimensional space occupied by the unit filter area is small, which can save a lot of space resources for the user and indirectly reduce the user’s one-time investment cost.

8. Long service life, the service life of the filter cartridge can reach 2 to 3 years, which greatly reduces the number of times the filter element of the dust collector is replaced (the traditional bag filter is replaced every 6 months on average), the maintenance is simple, and the maintenance is greatly reduced. The user’s maintenance cost during use.

9. This product is widely used for industrial dust in iron and steel metallurgy, non-ferrous smelting, construction cement, mechanical casting, food and light industry, daily chemical industry, tobacco, storage docks, industrial power station boilers, heating boilers, and municipal waste incineration industries. Purification and governance.

Structure

The cartridge type dust collector is composed of air inlet pipe, exhaust pipe, box body, ash hopper, ash cleaning device, diversion device, air flow distribution plate, filter cartridge and electric control device, similar to air box pulse bag dust removal structure. The arrangement of the filter cartridge in the dust collector is very important. It can be arranged vertically on the roof of the cabinet or inclined on the top. From the perspective of the cleaning effect, the vertical arrangement is more reasonable. The lower part of the roof is the filter chamber, and the upper part is the air box pulse chamber. An air distribution plate is installed at the entrance of the dust collector.

Working Principle

After the dust-containing gas enters the dust hopper of the dust collector, due to the sudden expansion of the air flow cross-section and the effect of the air distribution plate, a part of the coarse particles in the air flow settle in the ash hopper under the action of dynamic and inertial forces; the fine-grained and low-density dust particles enter the dust filter chamber. Through the combined effects of Brownian diffusion and sieving, the dust is deposited on the surface of the filter material, and the purified gas enters the clean air chamber and is discharged by the exhaust pipe through the fan. The resistance of the cartridge filter increases with the increase of the thickness of the dust layer on the surface of the filter material. Clean the dust when the resistance reaches a certain specified value. At this time, the PLC program controls the opening and closing of the pulse valve. First, a sub-chamber lift valve is closed to cut off the filtered air flow, and then the electromagnetic pulse valve is opened. The compressed air and a short period of time are rapidly expanded in the upper box and poured into the filter cartridge to make the filter cartridge The expansion and deformation produce vibration, and under the action of the reverse air flow, the dust attached to the outer surface of the filter bag is peeled off and falls into the ash hopper. After the dust removal is completed, the electromagnetic pulse valve is closed, the poppet valve is opened, and the chamber returns to the filtering state. The cleaning is carried out in each chamber in turn, and a cleaning cycle starts from the cleaning of the first chamber to the beginning of the next cleaning. The fallen dust falls into the ash hopper and is discharged through the ash unloading valve.

The dust removal process of the filter cartridge dust collector is to first cut off the clean air outlet channel of a certain room, make the room in a static state, and then perform compressed air pulse back-blowing to clean the dust, and then a few seconds after the dust removal After the natural settlement, the clean air outlet channel of the chamber is opened again, which not only cleans the dust completely, but also avoids the secondary adsorption of dust generated by the spraying and cleaning, so that the dust is circulated from room to room.

The selection of dust collector

1. Determination of filtration wind speed

Filtering wind speed is one of the key parameters for the selection of dust collectors. It should be determined according to the nature, particle size, temperature, concentration and other factors of dust or smoke in different applications. Generally, the inlet dust concentration is 15-30g/m3. The filtering wind speed should not be greater than 0.6~0.8m/min; the inlet dust concentration should be 5~15g/m3, and the filtering wind speed should not be greater than 0.8~1.2m/min; the inlet dust concentration should be less than or equal to 5g/m3, and the filtering wind speed should not More than 1.5~2m/min. In short, when selecting the filter wind speed, in order to reduce the resistance of the equipment, generally the filter wind speed should not be selected too large.

2. Filter material

JWST cartridge filter adopts PS or PSU polymer coated fiber filter material. When the filtered gas is at room temperature or below 100°C, PS polymer coated fiber filter material is generally used. If it is used in high temperature applications, it should be used. PSU polymer coated fiber filter material, if used in occasions with special requirements, it must be stated before ordering, and the filter material should be selected separately.

3. Ash discharge form

JWST series filter cartridge dust collectors all use screw conveyors to discharge ash (the dust collectors of rows 1-5 use star dischargers to discharge ash).

The filter element recovery system is a fan that draws away the air containing powder, filters it through an air filter, and then uses a pulse circuit for automatic control. The powder adsorbed on the air filter element during powder spraying will be Blow down with high-pressure airflow.

Product model

JT-LT-4

JT-LT-8

JT-LT-12

JT-LT-18

JT-LT-24

JT-LT-32

JT-LT-36

JT-LT-48

JT-LT-60

JT-LT-64

JT-LT-112

JT-LT-160

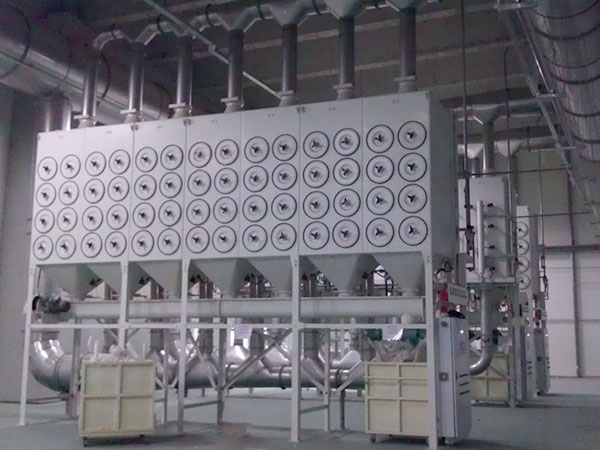

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as theory of "quality the basic, have faith in the initial and administration the advanced" for Rapid Delivery for Dust Collector Motors - Cartridge Dust Collector – Jiongcheng, The product will supply to all over the world, such as: New Delhi, Afghanistan, Cannes, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.