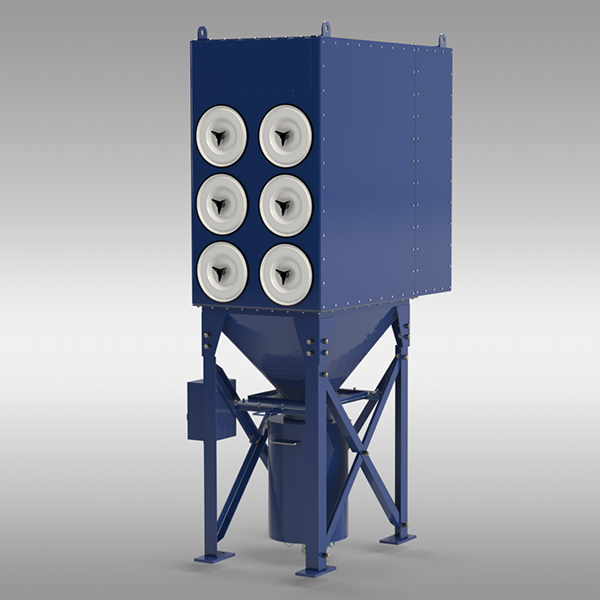

Trending Products Reliant Dust Collector - Cyclone Dust Collector – Jiongcheng

Short Description:

Trending Products Reliant Dust Collector - Cyclone Dust Collector – Jiongcheng Detail:

Cyclone

The cyclone dust collector is a device that uses the centrifugal force generated by the rotating motion of the dust-containing airflow to separate and trap dust particles from the gas.

Features

The cyclone dust collector has simple structure, no moving parts, The advantages of high dust removal efficiency, strong adaptability, convenient operation and maintenance, etc. It is one of the most widely used dust removal equipment in industrial applications. Under normal circumstances, the cyclone dust collector captures dust particles above 10μm, Its dust removal efficiency can reach 50~80%.

Working Principle

The dust-containing air flow of the ordinary cyclone dust collector enters the dust collector from the tangential direction from the intake pipe. After the spiral vortex is formed between the inner wall of the dust collector housing and the outer wall of the exhaust pipe, it rotates downwards. Under the action of centrifugal force, Dust particles reach the inner wall of the shell and fall into the ash hopper along the wall under the combined action of downward swirling airflow and gravity, and the purified gas is discharged through the exhaust pipe.

Applicable Industry

Wood industry, food, feed, leather, chemicals, rubber, plastics, grinding, casting, boilers, incinerators, kilns, asphalt mixing, cement, surface treatment, electronics, semiconductors, etc.

It is suitable for the separation and pretreatment of coarser particles or coarse and fine powders.

Such as: sawing, sanding and grinding powder; cloth shavings, wood shavings, copper wire ends, etc.

When the airflow is rotating, the dust particles in the airflow will be separated from the airflow by centrifugal force. The technology that uses centrifugal force to remove dust is called centrifugal dust removal technology. The equipment that uses centrifugal force to remove dust is called a cyclone dust collector.

After the cyclone dust collector enters the device along the tangential direction, the dust particles are separated from the gas due to the centrifugal force to achieve the purpose of flue gas purification. The airflow in the cyclone dust collector has to repeatedly rotate many times, and the linear velocity of the airflow rotation is also very fast, so the centrifugal force on the particles in the rotating airflow is much greater than gravity. For cyclone dust collectors with small diameter and high resistance, the centrifugal force can be up to 2500 times greater than gravity. For cyclone dust collectors with large diameter and low resistance, the centrifugal force is more than 5 times larger than gravity. The dust-laden gas generates centrifugal force during the rotation process, throwing dust particles with a relative density greater than that of the gas toward the wall. Once the dust particles contact the wall, they lose the radial inertial force and fall along the wall by the downward momentum and downward gravity, and enter the ash discharge pipe. When the rotating and descending external swirling gas reaches the cone, it moves closer to the center of the dust collector due to the contraction of the cone. According to the principle of constant “rotating moment”, the tangential speed is continuously increased, and the centrifugal force on the dust particles is also continuously strengthened. When the airflow reaches a certain position at the lower end of the cone, it starts from the middle of the cyclone separator in the same direction of rotation, reverses from the bottom to the top, and continues to make a spiral flow, that is, the internal swirling airflow. The post-purified gas is discharged out of the pipe through the exhaust pipe, and a part of the dust particles that have not been trapped are also discharged from this.

The performance of the cyclone dust collector includes three technical performances (processing gas flow Q, pressure loss △Þ and dust removal efficiency η) and three economic indicators (infrastructure investment and operation management costs, floor space, and service life). These factors need to be fully considered when reviewing and selecting cyclone dust collectors. The ideal cyclone dust collector must technically meet the requirements of process production and environmental protection for gas dust concentration, which is the most economical. In the specific design and selection of the form, it is necessary to combine the actual production (gas dust content, dust nature, particle size composition), refer to the practical experience and advanced technology of similar factories at home and abroad, and comprehensively consider the relationship between the three technical performance indicators. For example, when the dust concentration is high, as long as the power allows, improving the collection efficiency η is the main thing. For coarse dust with large separated particles, it is not necessary to use a high-efficiency cyclone dust collector to avoid large kinetic energy loss.

The cyclone dust collector is composed of an intake pipe, an exhaust pipe, a cylinder, a cone and an ash hopper. The cyclone dust collector is simple in structure, easy to manufacture, install, maintain and manage, and has low equipment investment and operating costs. It has been widely used to separate solid and liquid particles from airflow, or to separate solid particles from liquid. Under normal operating conditions, the centrifugal force acting on the particles is 5 to 2500 times that of gravity, so the efficiency of the cyclone dust collector is significantly higher than that of the gravity sedimentation chamber. Based on this principle, a cyclone dust removal device with a dust removal efficiency of over 80% has been successfully developed. Among the mechanical dust collectors, the cyclone dust collector is the more efficient one. It is suitable for the removal of non-sticky and non-fibrous dust, mostly used to remove particles above 5μm. The parallel multi-tube cyclone dust collector device also has a dust removal efficiency of 80-85% for 3μm particles. The cyclone dust collector is made of special metal or ceramic materials that are resistant to high temperature, abrasion and corrosion, and can be operated at a temperature of up to 1000°C and a pressure of up to 500×105Pa. In terms of technology and economy, the pressure loss control range of cyclone dust collector is generally 500~2000Pa. Therefore, it belongs to the medium-efficiency dust collector and can be used for the purification of high-temperature flue gas. It is a widely used dust collector, which is mostly used in boiler flue gas dust removal, multi-stage dust removal and pre-dust removal. Its main disadvantage is the low removal efficiency of fine dust particles (<5μm).

Product detail pictures:

Related Product Guide:

Reliable quality and good credit standing are our principles, which will help us at a top-ranking position. Adhering to the tenet of "quality first, customer supreme" for Trending Products Reliant Dust Collector - Cyclone Dust Collector – Jiongcheng, The product will supply to all over the world, such as: Ukraine, Serbia, Portugal, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.